In many industries—ranging from manufacturing and mining to laboratories, oil and gas, and construction—the risk of hazardous gases poses a serious challenge. Toxic, flammable, or oxygen‑deficient atmospheres can endanger workers and cause catastrophic accidents if not properly managed. Gas detection systems serve as the frontline defense to identify and mitigate these hazards in real time. With the evolution of sensors, connectivity, and automation, businesses today have access to a wide range of technologies and approaches. Choosing the right system and implementing it effectively can drastically improve workplace safety and regulatory compliance.

Technology Options in Gas Detection

- Fixed Gas Detection Systems

- Installed permanently in a facility, fixed systems continuously monitor critical areas such as production floors, confined spaces, or storage units.

- They use electrochemical sensors, catalytic bead sensors, infrared detectors, or photoionization detectors depending on the targeted gases.

- Fixed systems are best for high‑risk locations where hazardous atmospheres could accumulate rapidly and require constant surveillance.

- Portable Gas Detectors

- Small, battery‑operated handheld devices, often worn on workers’ clothing or belts.

- Useful in confined underground spaces, tunnels, or during maintenance tasks where mobility is essential.

- They typically detect gases like carbon monoxide (CO), hydrogen sulfide (H₂S), oxygen levels, or combustible gases.

- These devices provide real‑time personal protection by alarming workers through sound, vibration, or visual signals.

- Single‑Gas vs. Multi‑Gas Detectors

- Single‑Gas Detectors: Affordable, lightweight, and easy to use, but limited to monitoring one substance.

- Multi‑Gas Detectors: More versatile and often capable of tracking four to six gases simultaneously. These are essential in complex industrial operations such as refineries or chemical plants, where multiple risks exist.

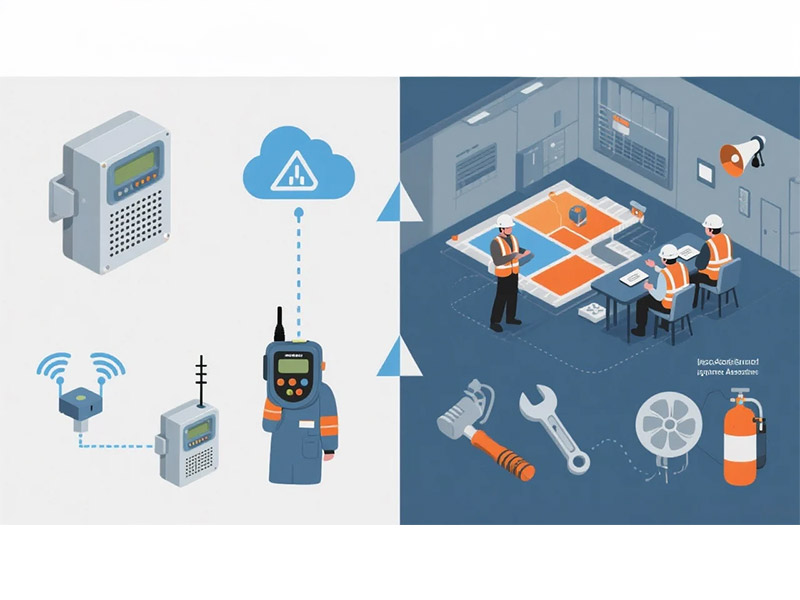

- Wireless & Networked Detection

- Integrating detectors with IoT (Internet of Things) platforms is a rising trend.

- Wireless gas monitors communicate with centralized software dashboards, enabling remote tracking, real‑time alerts, and predictive analytics.

- This approach enhances visibility across multiple facilities and reduces emergency response times.

- Advanced Detection Technologies

- Infrared (IR) Sensors: Reliable for detecting hydrocarbon gases and CO₂, especially in environments where catalytic sensors could degrade.

- Photoionization Detectors (PIDs): Effective for volatile organic compounds (VOCs) at very low concentrations.

- Ultrasonic Detectors: Detect high‑pressure gas leaks through sound waves rather than gas concentration, suitable for open or ventilated areas.

Implementation Strategies for Work Environments

- Risk Assessment and Hazard Mapping

- Before deploying gas detection systems, companies must conduct thorough risk assessments.

- Identify potential leak sources—such as pipelines, valves, or confined spaces—and map high‑risk zones. This ensures detectors are positioned strategically.

- Layered Detection Approach

- Combining fixed and portable systems provides the highest level of safety.

- Fixed monitors safeguard high‑risk zones, while portable units protect individual workers in dynamic environments where fixed coverage may not suffice.

- Maintenance and Calibration

- Sensors must be routinely inspected, cleaned, and calibrated against known gas concentrations to ensure reliability.

- Implementing automated bump tests and calibration stations can streamline this process and reduce system downtime.

- Training and Worker Engagement

- Technology alone is ineffective without trained personnel.

- Workers should understand how to wear portable devices, respond to alarms, and follow evacuation protocols.

- Regular drills coupled with safety training solidify proper usage habits.

- Integration with Safety Systems

- The most advanced implementations link gas detection to broader safety controls.

- For example, a high reading of flammable gases might automatically trigger ventilation fans, shut down specific machinery, or activate plant‑wide alarms.

- Compliance and Standards

- Systems should be designed to meet regional regulatory standards (e.g., ATEX in Europe, OSHA and ANSI in the U.S.).

- Certification ensures not only legal compliance but also heightened credibility with stakeholders and reduced liability risks.

Future Outlook

Gas detection technology will continue advancing with the integration of AI, machine learning, and predictive analytics. These tools will analyze past and real‑time data to forecast leaks before they occur. Additionally, miniaturized sensors and cloud‑based monitoring solutions promise greater accessibility for small‑ and medium‑sized enterprises. In the era of smart factories and Industry 4.0, gas detection systems will increasingly be part of a unified safety ecosystem—complementing fire alarms, HVAC monitoring, and building management systems.

Conclusion

Gas detection systems are critical components of workplace safety, particularly in industries where toxic, combustible, or oxygen‑deficient atmospheres are risks. Organizations must carefully assess their environment to select the right blend of fixed, portable, and advanced detectors. Equally important are strategies such as proper placement, regular calibration, workforce training, and integration with broader safety systems. By adopting a proactive, layered approach, employers not only protect their personnel but also secure operational continuity, regulatory compliance, and long‑term business resilience.